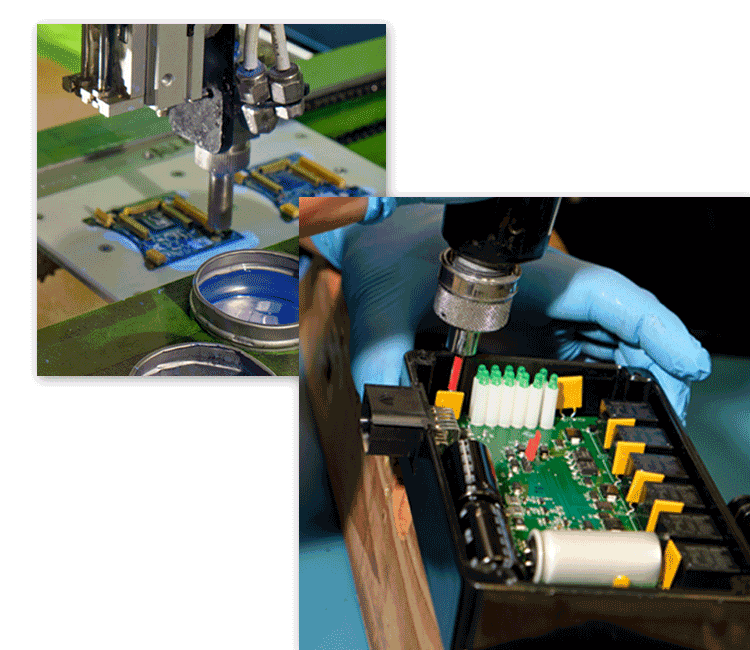

Manufacturing Service Solutions

Veris is the top choice for your high-reliability, high-quality, and complex assemblies. We specialize in advanced manufacturing, creating specialized service programs that fit the unique needs of each customer. When it absolutely has to work the first time and every time, Veris is your partner of choice.

-

Customized Service Solutions

-

Flexibility

-

Dedicated Program Management

Our Certifications

(click below to view credentials)

Markets Served

-

Nadcap & Space Addendum

-

RF Specialists

-

Advanced & Complex Mfg

Space

Aerospace

Medical

Military &

Defense

Telematics

Test &

Measurement

Automotive

Program Management Solutions

Dedicated Program Managers

We have outstanding quality. We have competitive pricing. We have on time delivery. All your EMS providers will promise you this and we will too. These are the gold standards for an EMS provider and a baseline that must be adhered to at all times. That is the easy part. There are so many other factors that can play into an OEM’s decision regarding their EMS Partner. We know our advantage is service and flexibility. It’s a simple solution for us; we do what the customer requires, when they require it.

We have solutions for these common EMS pitfalls. We will have a dedicated Program Manager assigned to each and every account. You will have 1 well trained and experienced Program Manager you can call for all requirements and projects. Beyond that, we train all our Program Managers to IPC standards and to always use our key phrase “Does that work for you?” If the answer is no, we go to great lengths to find the solution that does. We take time to understand what our customer’s unique needs are and work with our internal team to meet them. Our Program Managers will ask all the needed questions up front in our customer or project Pre-Launch to make sure we meet all expectations. We find its key to get all your expectations and deadlines up front and known, so that we may communicate our progress to you and keep you informed. This clear line of communication is the driving force behind our success.

You need organized answers in real time. You need a Program Manager you can trust to get you the data you need, when you need it. We understand this, and pride ourselves on our responsiveness and flexibility. Please contact us today to see how we can design a customer-centric program launch for you.